Make value flow with pull systems

- Rafael Sabbagh

- Jan 20, 2024

- 3 min read

Updated: May 16, 2024

Are you being pushed with more tasks than you can finish, regardless of how busy you already are, and work is piling up? If so, you are probably working in a push system! In this article, I will explain how pull systems work and why they are better than traditional push systems. This article is full of images and animated GIFs to help you better understand the concepts.

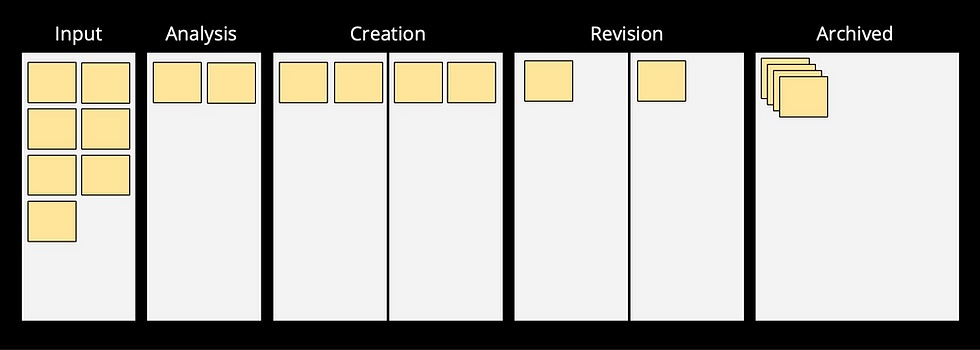

The following is the representation of a simple workflow. In this example, the work item enters the Input stage, then it moves to Analysis, then to Creation, and then to Revision. When they are done revising it, it's moved to Archived.

The stages in green shown below are actual work stages. So, someone is working on the item when it is in any of those stages. The other stages are wait stages, which means they are queues (except the Archived stage, which is the final one). Items are waiting there for someone to pick them up and start working on them.

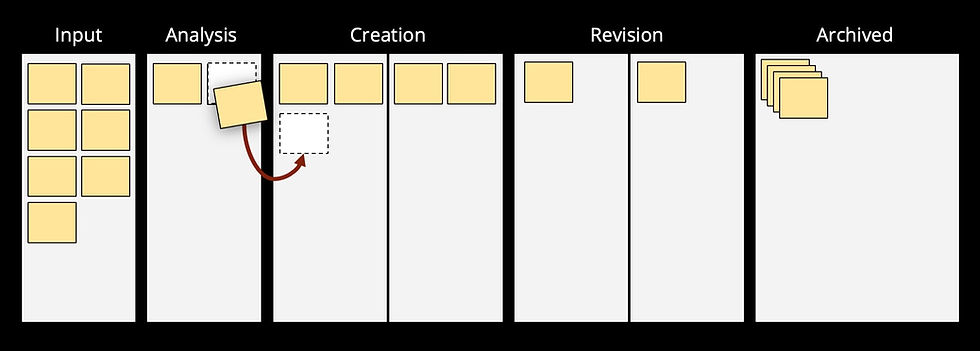

I will start by explaining the main problems with the traditional push system. Let's say whoever is working in the Analysis stage is done with analyzing the item. They will push it to the Creation stage.

And it will be placed on the queue of that stage. Now, Analysis can pick another item from Input, their backlog.

Let's say Analysis is much faster than Creation. Therefore, they keep picking items from Input, getting them done on the Analysis, and then pushing them towards Creation. Items start to accumulate there.

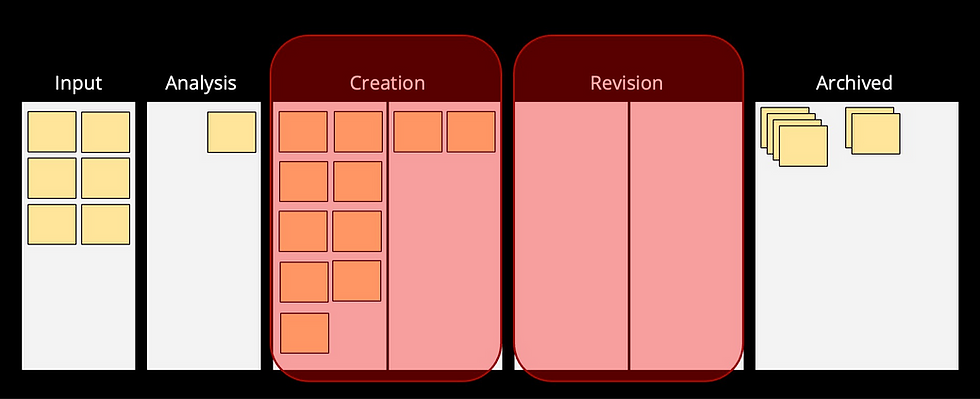

At this point, we can see two different problems. One is that Creation in this workflow is clearly a bottleneck. Things are not moving out of there, or at least not fast enough. And the other problem is that Revision is under starvation. As items are not moving fast enough out of Creation, at some point, Revision has nothing to work with.

In a bigger system, in a complex organization, imagine that happening in several different places!

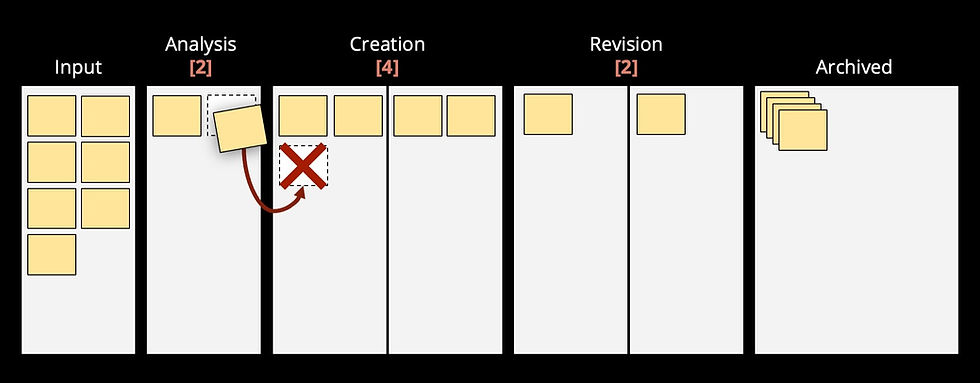

Now let's see how a pull system would better work for our workflow. I will first introduce a concept called "WIP limits." WIP stands for Work in Progress or Work in Process. And WIP Limit is actually the maximum number of items that can be under a stage or a set of stages.

In our example workflow, the WIP Limits are stated right below the stage names. There, you can see that a maximum of two items can be under Analysis. The maximum of four items can be under Creation, either on their queue or on the working stage. And, just the same, a maximum of two items can be under Revision. And you can see that, at this moment, they are all on their limits. Analysis has two items. Creation has four items. Revision has two items.

So, at this particular moment, if the items under Analysis are done, they cannot be moved to Creation. It is not allowed, as it would exceed their limit. Since Analysis are at their limit, they cannot pull another item from Input either. But then, what should people doing analysis do? Well, maybe do something else, improvements, research, study, or... help other people on that workflow! Since both Revision and Creation are at their limits, why not lend a hand there to help the flow?

But now let's say an item under revision is done. It will be moved to the stage Archived - there are no limits there. And Revision will pick the next item on their queue to work on. But see, this opens a room on the Revision stages. They have one item there, but their WIP limit is two!

If there is at least one item done on the Creation stages, Revision will pull an item from there. Let's say there is one and they will pull it. And now this has opened a room on the Creation stages. Their WIP limit is four, but they have only three items there. If there is an item done on the Analysis stage, Creation will now pull an item from there, which will open room at that stage. And now Analysis can pick a new item from Input.

You see how the movement on the Revision stages has created movement on the entire workflow. This made items flow! With that, we can calibrate the WIP limits to avoid bottlenecks and starvation. And by doing this, we can achieve a continuous flow of value. This is one of the core principles of the Kanban method and the Toyota production system.

As we've seen in this example, the implementation of pull systems with the use of WIP limits not only optimizes the flow of work but also transforms the way teams interact with their work items. It's a shift from a reactive to a proactive approach, where efficiency and productivity are not just goals, but integral parts of the process.

Comments